Flux Core Welding SHEET METAL YouTube

Easy peasy! Power Source and Flux Core Wire:The Arccaptain runs on 220V power, giving you the juice needed for flux core welding adventures. Now, about that flux core wire - go for the good stuff, like the 30th Y8mm E71T-GS. It's the secret sauce for optimal welding performance.

5 Tips for Flux Core Welding Beginners How to Weld with Flux Core YouTube

Flux core welding is a revolutionary process that enables welders to join metal components together with exceptional strength. From thin gauge sheet metal to thick steel plates, flux core welding with a welder can create powerful, permanent bonds. This process offers an efficient, cost-effective way to join metals in a wide range of applications, from automotive repairs to industrial.

Flux Core Welding How To, What Is It, Tips Maritime Herald

How to weld sheet metal with flux core We've now got the essential part of welding sheet metal with flux core covered. It's time to deep dive into the steps. Prepare your workpiece Always start with cleaning your sheet metal, whether you're working on new or used sheet metal.

Flux Cored Arc Welding (5 Basic Tips) Venus Wires

WELD-PAK® 180HD. K2515-1. The WELD-PAK® 180HD wire feeder welder from Lincoln Electric is setup for welding thin steel, stainless or aluminum sheet metal with MIG or thicker steel with flux-cored welding. Output.

How To Weld Sheet Metal With Flux Core Wire For Beginners Flux Core Welding Tips And Tricks

Metal preparation for flux-cored welding. As mentioned earlier, flux-cored welding is more tolerant of surface contamination than MIG welding. However, you should always clean the surface of the base metals as thoroughly as possible to ensure that a rusty or scaly surface does not contaminate the final weld.

Welding THIN Material with Flux Core YouTube

Welding sheet metal, skinny gauge, is a valued skill with numerous applications in automotive and HVAC industries. The flux core welding method, known as FCAW (Flux-Cored Arc Welding), offers advantages like deep penetration and a forgiving nature when dealing with rusty or dirty metal.

Advanced Gas Metal Arc Welding (GMAW) and Flux Cored Arc Welding (FCAW) Baker Technical Institute

Free Shipping Available. Buy Flux Weld on ebay. Money Back Guarantee!

Harbor Freight MIG 170 Flux Core Welding 1/8 Steel YouTube

Over 1 day Flux core welding uses a hollow wire electrode fed through the welding gun and into the joint. It has a variety of benefits over standard welding. The flux core process also doesn't require a shielding gas to protect the weld pool. This guide explores flux core welding and how it is a useful skill for DIYers. SHOP WELDING SUPPLIES NOW

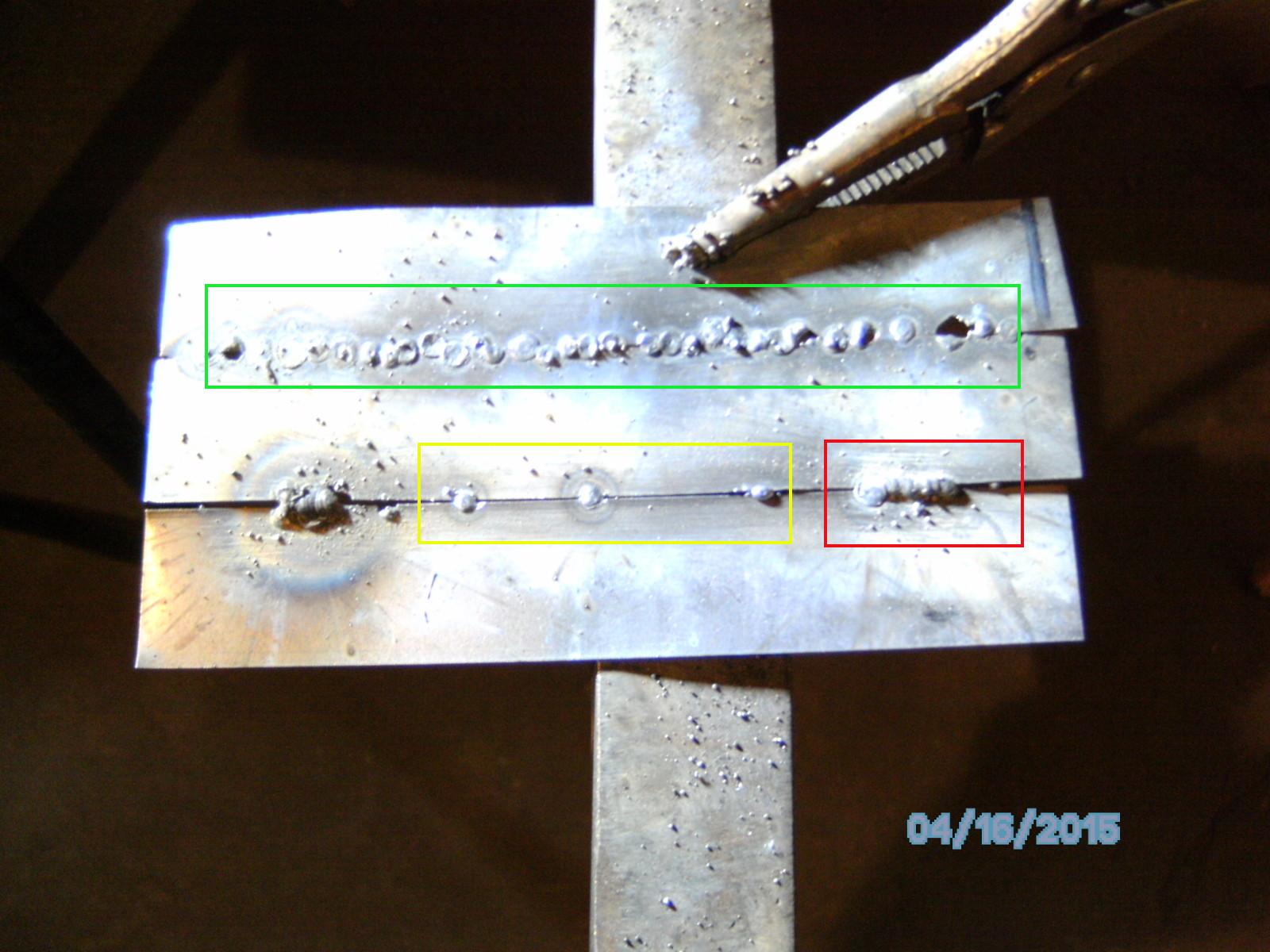

Gallery Fluxcore sheet metal welding 22 gauge butt seam

Project Ideas Cutting 14 Flux Core Welding Tips & Tricks for Beginners By: Jeff Grill

Flux Cored Arc Welding Basics YouTube

Wondering if it's possible to butt weld automotive sheet metal with a flux core welder? This video can help answer that question by using a $99 Harbor Freig.

Welding Common Joints Using Flux Cored YouTube

There are some ways to increase your chances and make it happen. SHOULD YOU WELD BODY PANELS WITH FLUX CORE? Most people will not recommend welding body panels with flux core. This is due to the thinness of body panels, which can range into some pretty thin sheet metals depending on the car you are working on.

Flux Core Welding Basics Blain's Farm & Fleet Blog

#welddotcomLets weld some thin material with flux core!Join Weld.com today, get member's perks and support the community! https://www.youtube.com/channel/UCM.

Flux Core Welding Stainless Steel To Mild Steel

The flux makes a shield on the surface and makes a strong hold. This is why there is no need for a gas tank for the flux core. People have a traditional belief in them that only stick welding is the best method to do outdoor welding. The flux core welding method has changed the situation now. You can weld by this technique by being careful and.

Flux core welding YouTube

You must have at least 5% CO2 for steel to stabilize the arc. Avoid flux-cored wires because they input far more heat into the metal. The flux-cored wires are hollow. The cross-sectional area of the steel wire is small, which increases the current (heat) concentration flow into the welding pool.

How To Weld Sheet Metal With Welding Machine Step by Step Guide

Weld Thick, Thin, Reflective and Dissimilar Metals: Aluminum, Steel, Copper, Titanium, Etc. LightWELD Delivers Fast, Consistent Aluminum Welds Without Distortion or Cracking

What is Welding? Definition, Processes and Types of Welds TWI

Subscribed 114K views 3 years ago Today we're flux core welding sheet metal. Last time we did a thin gauge flux core welding video we used 1/8" and got completely hammered for it not being.